Industrial Coffee Grinder: Pros, Cons, and Features to Consider

Industrial Coffee Grinder: Pros, Cons, and Features to Consider

Blog Article

Leading Attributes to Seek in an Industrial Coffee Grinder

When reviewing a commercial coffee mill, it is crucial to identify vital features that impact both performance and longevity. Consistency in work size is essential for optimal extraction, while adjustable grinding rate permits for a balance between efficiency and quality.

Grind Size Consistency

While numerous aspects can influence the high quality of brewed coffee, grind dimension consistency continues to be critical in achieving ideal extraction. The uniformity of coffee premises straight influences the brewing procedure, as uneven bit dimensions can bring about over-extraction or under-extraction. This variance results in imbalanced flavors, where certain notes might be overpowering while others are silenced.

Industrial coffee grinders are made to provide a high degree of accuracy, commonly using burr grinding mechanisms to make sure a consistent work dimension. Unlike blade mills, which can create a mix of penalty and coarse fragments, burr mills crush the beans between 2 surfaces, permitting much better control over work size. This consistency is vital across different developing techniques, whether espresso, French press, or pour-over, as each technique needs details work sizes for ideal flavor removal.

Moreover, uniformity in work dimension adds to the general effectiveness of the developing procedure. An uniform work permits also water flow, lowering the risk of transporting and improving extraction effectiveness. In summary, purchasing an industrial coffee grinder with a concentrate on work size consistency is necessary for achieving top quality coffee with preferable taste accounts.

Grinding Rate

Grinding speed plays a crucial duty in the general performance of commercial coffee mills, straight impacting both the top quality of the grind and the performance of the operation. Industrial Coffee Grinder. Higher grinding rates can considerably boost the throughput, making it possible to refine larger amounts of coffee beans in a much shorter amount of time. This is especially important for organizations that count on high-volume manufacturing, such as coffee roasteries and coffee shops

However, while rate is necessary, it is equally vital to stabilize it with the high quality of the work. Exceedingly high grinding speeds can create heat, which may detrimentally affect the taste profile of the coffee by triggering the beans to lose vital oils and fragrances. A mill that provides adjustable speed setups can offer optimum adaptability, permitting drivers to tailor the grinding procedure according to details needs.

Additionally, the grinding speed ought to be consistent to guarantee uniformity in the grind size, more contributing to the overall taste and developing top quality of the coffee. In recap, evaluating grinding rate is crucial for choosing an industrial coffee mill that fulfills both performance and high quality demands.

Build Top Quality and Durability

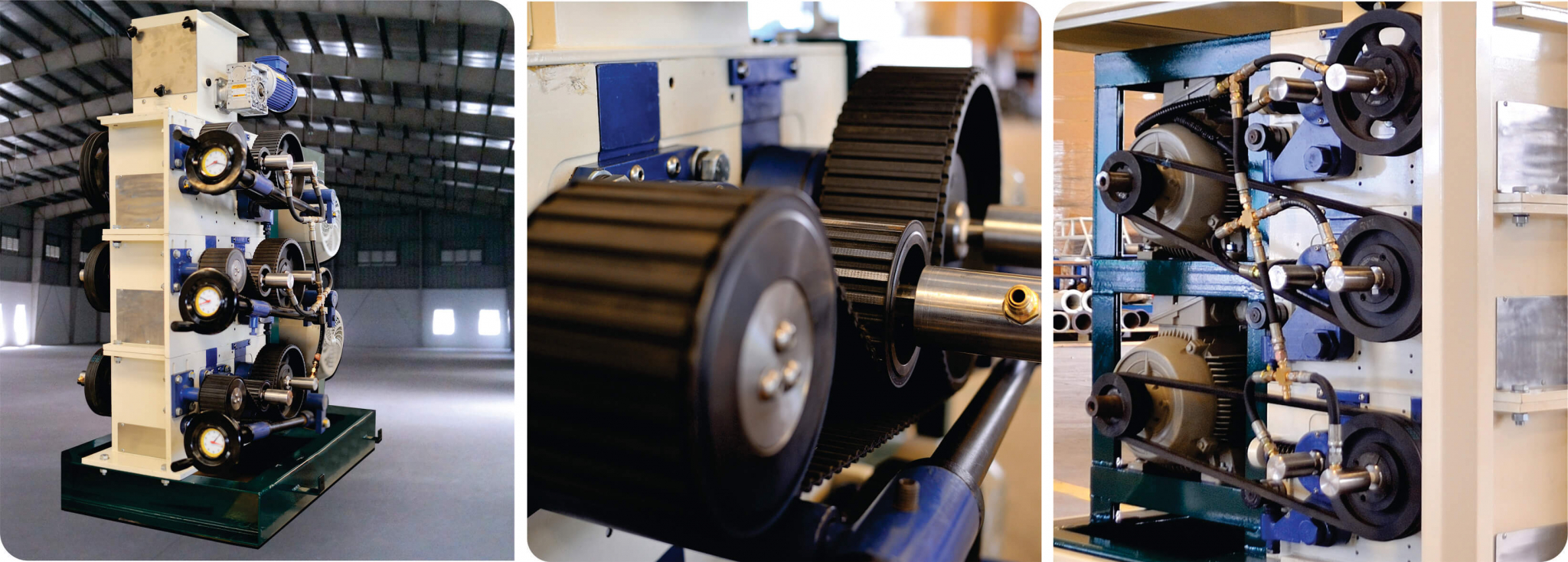

The efficiency of an industrial coffee grinder is not entirely determined by its grinding speed; build quality and toughness are equally vital aspects that influence lasting performance and integrity. A sound grinder will certainly endure the roughness of everyday usage, making it an audio financial investment for any type of commercial operation.

Resilience also includes the grinder's electric motor and internal devices. Industrial coffee grinders must be geared up with sturdy electric motors with the ability of sustaining extended operation without overheating. Additionally, durable burrs are necessary, as they straight influence the quality of the grind and add to the overall long life of the maker.

Simplicity of Usage and Maintenance

Constantly focusing on simplicity of use and get more maintenance can dramatically improve the functional efficiency of an industrial coffee mill. Straightforward features such as instinctive controls and clear labeling are necessary for lessening downtime and making certain that operators can quickly adjust to the devices. An ergonomic layout, including height-adjustable receptacles and obtainable grinding chambers, enables for comfortable procedure and promotes the loading and discharging of coffee beans.

In addition, convenience of maintenance is important for extending the lifespan of the grinder. Tools with detachable parts and elements made for fast cleansing can simplify maintenance tasks, decreasing the moment invested on regular maintenance - Industrial Coffee Grinder. Try to find grinders that integrate self-cleaning systems or require very little disassembly, as these functions can save useful labor hours

In addition, clear maintenance routines and paperwork are essential. Grinders that include comprehensive individual guidebooks outlining maintenance treatments can aid drivers abide by finest methods, ensuring constant performance and quality. By spending in a commercial coffee mill that emphasizes simplicity of usage and upkeep, organizations can improve performance, lower functional prices, and keep the high criteria anticipated in coffee production.

Sound Level Reduction

When picking a commercial coffee grinder, noise level decrease is an important aspect that can substantially influence the workplace. High sound degrees can lead to worker tiredness, minimized focus, and possible hearing damages over time, making it necessary to pick a mill created with sound-dampening functions.

Search for grinders that integrate sophisticated noise-reduction innovations, such as sound-insulated housings and vibration-dampening installs. These features aid to lessen operational sounds, developing a quieter ambience helpful to performance. Industrial Coffee Grinder. our website Additionally, choosing grinders geared up with low-noise electric motors can even more boost audio decrease, making certain an extra enjoyable functioning environment

Think about the mill's general design. The placement of the mill within the work space must be strategic.

Ultimately, buying a coffee mill that prioritizes noise reduction not only enhances the comfort of employees but likewise aligns with a dedication to keeping a risk-free and efficient job atmosphere. This focus to detail can bring about improved staff member satisfaction and retention.

Final Thought

In recap, choosing an industrial coffee grinder demands cautious consideration of a number of essential attributes. Grind dimension uniformity is necessary for ideal removal, while adjustable grinding rate helps with an equilibrium between throughput and high quality. The option of products directly influences construct high quality and toughness, making sure long life in a demanding setting. Simplicity of usage and maintenance, along website link with noise reduction modern technologies, boost functional effectiveness and comfort. Focusing on these functions will certainly lead to a much more reliable grinding solution.

Industrial coffee grinders are made to offer a high level of precision, usually utilizing burr grinding mechanisms to make certain an uniform grind size. Unlike blade mills, which can develop a mix of fine and coarse particles, burr mills crush the beans between two surface areas, allowing for better control over grind dimension. In recap, spending in an industrial coffee grinder with an emphasis on grind size uniformity is necessary for accomplishing top quality coffee with preferable flavor profiles.

Grinding speed plays a vital duty in the total efficiency of industrial coffee mills, straight impacting both the high quality of the grind and the effectiveness of the operation. A mill that provides adjustable speed settings can supply optimum versatility, enabling operators to tailor the grinding procedure according to particular needs.

Report this page